|

|

|

|

|

|||

|

|

|

using metal in gothic cathedral constructionrelated page: |

|

|

|

|

||

francecathedral labyrinths and mazes in France Germans

in France France’s western isles: Ile de Ré on first arriving in France - driving Marianne - a French national symbol, with French definitive stamps the calendar of the French Revolution the

6th bridge at Rouen: Pont Gustave Flaubert, the French umbrella & Aurillac the

forest as seen by francois mauriac, and today after

the whirlwind, in les landes |

Today, cathedrals may show the strains bring put on them by such pressures, Amiens being a well-catalogued example.

But buttressing was often not enough, especially if a buttress was mis-positioned - easy enough to do before the days of civil engineers trained in Newton's laws of physics. So to correct impending collapses, metal was used to strengthen and reinforce the cathedral's structure, as well as providing additional support. Iron ties held arches together, while a girdle made of forged iron 'links' held the cathedral's waist (usually at the triforium level) in trim. This page will discuss and illustrate how metal was and is an integral part of a structurally sound cathedral's construction. Keep in mind that the development of these structures was greatly mediated by trial and error. Of course, that is the way engineering develops, as can be seen to this day. These methods of using iron have been used in many cathedrals around Europe. Some indications can be found in this, rather sloppy, paper: The role of iron armatures in Gothic constructions: reinforcement, consolidation or commissioner's choice. forging the iron |

|||||||||||||||||||||||||||||||||

the forge building at the Abbey of Fontenay |

recreated water-powered trip hammer at the Fontenay forge |

|||||||||||||||||||||||||||||||||

The Abbaye de Fontenay at Montbard in the département of Côte-d'Or. Founded and run by Cistercian monks, the abbey complex includes the late 12th-century forge building. Over 50 metres long, it probably housed two furnaces, with several mills operating hydraulic hammers. The wrought iron supplied to Amiens cathedral and others was probably forged in a Cistercian workshop of this type. This forge is about 300 km from Amiens cathedral. Amiens cathedral was built between 1220 and 1266. [The Abbaye de Fontenay/Fontenay Abbey is at

Montbard 21500, tel. n°: 03 80 92 15 00,

fax n°: 03 80 92 16 88. chainage or stabilising rods, and buttressing

|

||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||

Pic du

Midi - observing stars clearly, A64 Carcassonne,

A61: world heritage fortified city Marianne - a French national symbol, with French definitive stamps the calendar of the French Revolution mardi gras! carnival in Basque country what a hair cut! m & french pop/rock country life in France: the poultry fair |

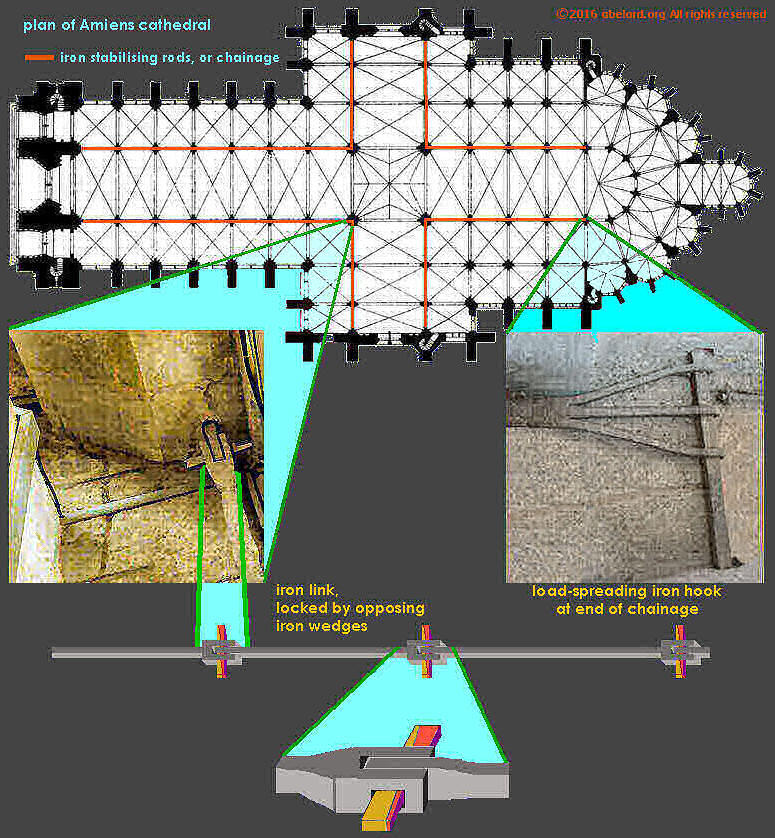

As the diagram above illustrates, the iron 'girdle', the ceinture de fer or iron belt, holds together the arches between in the nave and the two sides of the transept at Amiens cathedral. The 'girdle' is made up of solid iron rods, linked together by strong links, and set firmly into the fabric of the cathedral's stone structure at the end points. The rods were up to 4 metres long and had a cross-section of 4 by 8 cm. This iron chain, or chaînage, lies on the floor of the triforium running around the cathedral above the main bay arches. As can be seen in the illustration at the head of this section on chaînage, this is just above where cracks have appeared as parts of the cathedral shift apart. problems with chainageOriginally, the chainage that prevented arches collapsing from outwards pressures were made from wood, included in the cathedrals as they were built. In some cathedrals, like Saint-Denis and Notre Dame de Paris, there was such a retaining 'girdle' at each level of arches. Viollet-le-Duc, when supervising the dismantling of these cathedrals before restoring and rebuilding them, found quadrilateral-sectioned 'tunnels' through the cathedral structure left by the wood that had rotted away. As a result, and as the making and manipulation of iron developed, the wooden chainage was supplemented and replaced by iron. However, iron would also have its problems, rusting over time, or as Viollet-le-Duc described it,

This rusting was lessened by enveloping the iron with lead. A more modern rust protector for iron is red lead, that until recently could be seen protecting large structures such as the Golden Bridge at San Francisco and the Forth bridge in northern England. The red lead protection has now been replaced by modern alternatives. chainage at Sainte-ChapelleInterestingly, the chapel of Sainte-Chapelle in Paris incorporated a form of iron reinforcement, with two ‘chains’ of hooked bars encircling the upper chapel, the main part of the structure. Further, there were iron stabilisers across the nave (with a vertical tension bar).

Also, an impressive eight-pointed iron star helped hold the apse together. Its iron bars radiated from a central collar. (The drawings above and below were made by Jean-Baptiste-Antoine Lassus during the restoration of Sainte-Chapelle.)

Originally, the iron bars were much smaller, because the technology could not produce enough iron at one time to make longer bars. In those early days, the iron bars (called crampons) hooked one into the next.

As well as crampon bars with a hook at one end and eye at the other, there were also bars with two eyes or two hooks to enable all possibilities on connection, depending on the circumstance. stabilising and reinforcing tie rods - Saint Quentin, Westminster

Because of the rather dodgy stability of the gothic buildings, later additions of iron stabilisation can be seen in many cathedrals, for example at Westminster Abbey and in the cathedral at Saint Quentin. The tie rods at Saint Quentin are placed higher, nearer the apex of the Gothic arch, than those at Westminster Abbey. A lot of construction development, changes and even improvements, were a matter of trial and error.

It is of interest to note that, at Saint Quentin, the apse tie-rods were removed at the end of the 19th century, while those in the nave were kept. After the First World War shelling, the apse vaults collapsed, while for those in the nave the ribs survived, though the webs between them were damaged. After the cathedral was restored, the nave tie-rods were removed. Chartres roof space : le charpente de fer

On June 4, 1836, following the carelessness of plumbers who were making repairs, a fire broke out in the roofing timbers of Chartres cathedral. The fire spread quickly, destroying the wood frame, the forest, and the cathedral's lead roof. Fortunately, the fire did not advance into the bell tower. There, the great bell was not harmed, sounding for half an hour. Many lower bells were lost, to be replaced in 1840 and 1845 by those still rung today. The roof was replaced by a beautiful iron frame and a copper roof, built in metal for future safety and for economy, like the partial roof at Southwark Cathedral, London built during the restoration of 1822-25, and the cupola at Mayence [Mainz in Germany], built in 1827 (?). When built, the span over the cathedral's crossing (where the nave crosses the transept) was the largest of any iron-framed construction in Europe. The iron frame looks like a huge boat overturned. The framing has joists of wrought and cast iron, connected by rafters that ensure the rigidity of the structure. During the winter storm in 1997, a portion of the roof was torn and was long covered by tarpaulins. By December 2009, renovations were completed. The metal frame, having suffered from corrosion and expansion due to temperature changes, has been partially restored between 1995 and 1997 by Guy Nicot, chief architect of historical monuments.

Another method can be seen at Noyon cathedral with the roof off and the rather more tidy concreting, the modern idea of rubble. Of course, this much reduces the fire risk from the traditional and medieval forest. Rouen lantern tower

Elise Whitlock Rose commented about the lantern tower:

|

|||||||||||||||||||||||||||||||||

wrought iron, cast iron, and steelCast iron, wrought iron and steel - all are alloys of iron and carbo with other additions or contaminants. The carbon content of wrought iron is less than 1%, while that of cast iron is between about 2.4 and 4%. Its high carbon content makes cast iron very rigid in compression, but weak and brittle in tension, even when red hot, so it cannot be forged or rolled. Modern steel has a carbon content of up to 2.1%. Iron is extracted from naturally occurring ores. These provide the source compound, iron oxide (FeO). early mediaeval wrought ironBefore blast furnaces able to produce molten iron were invented at about 1500, iron ore was smelted in a bloomery. A bloomery consists of a pit or chimney with heat-resistant walls made of earth, clay, or stone. Near the bottom, one or more pipes (made of clay or metal) enter through the side walls, channelling in air to help the reduction process. These primitive furnaces could not reach the temperatures, above 1,150° C/2,100° F, needed to melt iron. This resulted in the product of a bloomery being a lump of semi-molten metal and slag, called a bloom. The earliest bloomeries produced only about 1 kg of iron at a time. Later, blooms could be made that weighed up to 5 kg/11 lb. Bloom is made of almost pure iron with impurities of entrapped slag and charcoal. This mix of semi-liquid slag and molten iron is called sponge iron. It was usually repeatedly hammered and reheated to drive off much of the liquid slag, to compress the remainder to fill the holes left in the iron by the slag, and to help align the iron molecules for greater strength. This consolidation is called shingling. In due course, the mixture was further forged into wrought iron. The inability to reach the melting point of iron made it difficult to manage the level of carbon and other impurities such as sulphur (particularly detrimental to the properties of iron). Thus, the iron's strength and properties could only be poorly controlled. The bloomery has now largely been superseded by the blast furnace, which produces pig iron. pig iron to cast ironWhen iron oxide is heated to high temperatures (870 to 1,650°C/1,600 to 3,000°F), the oxygen component of the ore combines with carbon, and the iron oxide is reduced to the element iron. Pig iron can be hammered and reheated, worked to make wrought iron. Pig iron can also be combined with scrap iron, then smelted - heated to high temperatures in a blast furnace to separate out impurities. Alloys, such as manganese, nickel, titanium, chromium, bismuth or copper, are added to form cast iron with differing characteristics. |

Dictionnaire raisonné de l'architecture française du XIe au XVIe siècle

by Eugène Viollet Le-Duc.press release for Gothic cathedrals blend iron and stone, CNRS, Paris. This document was published in the Journal of Archaeological Science in January 2015 with a longer title.

Consolidation or initial design? Radiocarbon dating of ancient iron alloys sheds light on the reinforcements of French Gothic Cathedrals

by Stéphanie Leroy, Maxime L'Héritier, Emmanuelle DelquéKolic, Jean-Pascal Dumoulin, Christophe Moreau, Philippe Dillmann. Journal of Archaeological Science vol. 53 (January 2015), pp. 190-201. DOI: 10.1016/j.jas.2014.10.016

Available as a .pdf from academia.edu. You sign in (abelard.org used the facebook button), the press "READ PDF" below. The pdf may not appear immediately.Cathedral of Bourges, and its place in Gothic Architecture

by Robert Branner

- The MIT Press, 1989

- ISBN-10: 026252130X

ISBN-13: 978-0262521307L'homme et la matière : L'emploi du plomb et du fer dans l'architecture gothique

by Arnaud Timbert

- Editions A & J Picard, large pbk, 2009

- ISBN-10: 2708408356

ISBN-13: 978-2708408357amazon.com

£28.62 [amazon.co.uk]

| abstracts | briefings | information | headlines | loud music & hearing damage | children & television violence | what is memory, and intelligence? | about abelard | ||

© abelard, 2016, 31 january the address for this document is https://www.abelard.org/france/using-metal-in-cathedral-construction.php 4100 words |